Warehouse management is often a balancing act between speed, safety, and space. As businesses grow and logistics demands evolve, the need for adaptable solutions becomes more pressing. Traditional fixed partitions or makeshift barriers can quickly become outdated or inefficient. Enter the Movable Barbed Wire Sorting Fence Nets — a versatile, durable, and dynamic tool designed to streamline warehouse operations and elevate productivity.

From Chaos to Control: How One Tool Can Redefine Your Warehouse Flow

In many warehouses, the absence of clear spatial boundaries leads to confusion, wasted time, and unnecessary risks. Employees may struggle to locate inventory, and temporary work zones often turn into long-term disarray. The introduction of a modular fencing system changes the game. Unlike permanent structures, these movable barbed wire sorting fence nets offer the flexibility to adapt to changing needs without compromising on safety or efficiency.

The Hidden Cost of Poor Warehouse Organization

Unorganized warehouse spaces can cost more than just time — they can impact profitability, employee morale, and even customer satisfaction. Without defined zones, inventory misplacement becomes common, and workers may inadvertently enter restricted areas. The result? Increased labor hours, higher error rates, and a greater risk of workplace injuries. With a dynamic partitioning system like the barbed wire sorting fence nets, you gain control over your warehouse layout, turning chaos into a well-orchestrated operation.

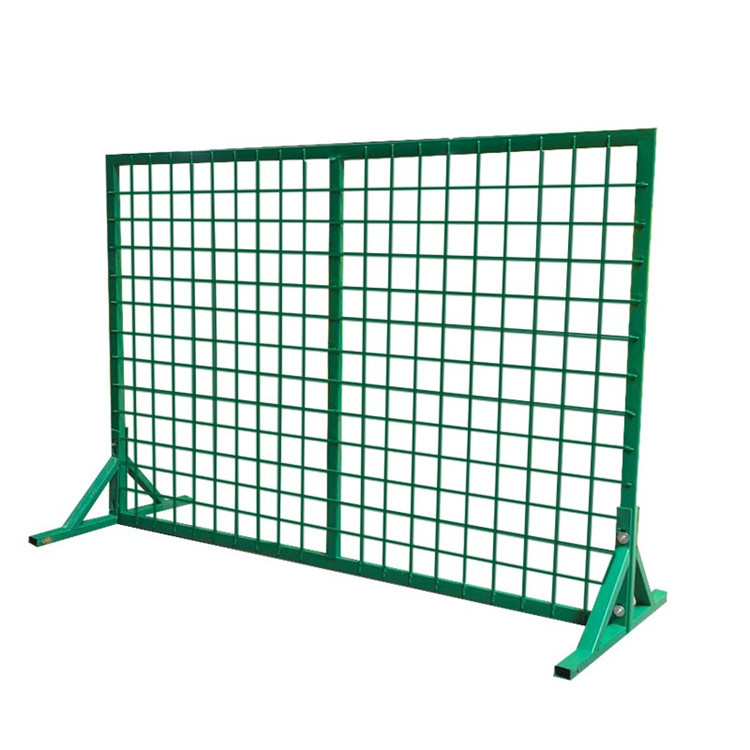

Meet the Game-Changer: Movable Barbed Wire Sorting Fence Nets

These innovative fence nets are engineered for performance and convenience. Their lightweight design allows for easy relocation, while the sturdy barbed wire mesh ensures durability even in high-traffic environments. Each unit is built to withstand pressure, resist wear and tear, and maintain structural integrity over time. The installation process is simple — no tools required — and they can be deployed in minutes, making them ideal for both long-term use and temporary setups.

Why Flexibility Matters: Adapting to a Dynamic Warehouse Environment

Modern warehouses are anything but static. Seasonal demand surges, promotional events, and fluctuating inventory levels require a space that can evolve with the flow. Movable fence nets allow you to create temporary sorting zones, buffer areas, or secure storage pockets in a matter of minutes. For instance, during peak e-commerce seasons, companies can quickly set up express sorting stations to handle the influx of orders — and just as easily dismantle them when the rush is over.

Safety Meets Efficiency: Protecting Your Team and Inventory

One of the most critical benefits of these fence nets is the enhanced safety they provide. By clearly demarcating work zones, they prevent unauthorized access to hazardous areas and reduce the likelihood of accidents. In a case study involving a medium-sized manufacturing plant, the implementation of movable barbed wire fencing led to a 30% reduction in workplace incidents over six months. Not only did safety improve, but employees also reported a more organized and intuitive working environment.

Beyond the Fence: Creative Uses in Factories and Storage Yards

While their primary function is to enhance sorting and inventory control, these fence nets have proven to be highly versatile. Companies have repurposed them for everything from temporary rest areas for workers to exhibition space dividers. Some logistics centers have even used them to create quarantine zones for damaged or recalled goods. This adaptability not only increases the return on investment but also makes the product an essential tool for smart space management.

Sorting Simplified: How This Tool Supercharges Your Logistics Workflow

With the rise of “Express Sorting” in the logistics industry, speed and accuracy have become more important than ever. These fence nets enable teams to establish clearly defined sorting lanes, reducing the risk of cross-contamination and misrouting. The visual clarity they provide helps workers stay focused and efficient, ultimately shortening the time it takes to process each order. Compared to traditional fixed fencing, which is often time-consuming to install and difficult to modify, movable nets offer a superior balance of agility and structure.

Designing a Smarter Warehouse: Integrating the Fence into Your Layout

Integrating these fence nets into your warehouse layout doesn’t require a complete overhaul. Start by identifying high-traffic zones or areas where temporary partitions would improve workflow. Whether you're managing a small distribution center or a sprawling logistics hub, these nets can be arranged to suit your unique spatial needs. For compact spaces, consider using them to create rotating zones that adapt to daily or weekly demand shifts.

Real Stories, Real Results: Customer Insights from the Field

One logistics company reported a 25% increase in sorting efficiency after adopting these fence nets across multiple facilities. Another large-scale manufacturer saw a noticeable drop in safety incidents, attributing the change to clearer zone delineation and improved worker awareness. These stories highlight how a simple tool can make a measurable impact on both operational performance and workplace culture.

Future-Proof Your Space: The Long-Term Value of a Modular Solution

As the logistics industry moves toward more modular and intelligent warehouse designs, adaptable tools like the movable barbed wire sorting fence nets are becoming essential. They support not only current operational needs but also future scalability. Whether you're preparing for automation, expanding your product lines, or adjusting to new safety regulations, these nets offer a flexible foundation that grows with your business. Investing in modular infrastructure today ensures you're ready for tomorrow’s challenges.