Modern warehouses face an ever-evolving set of challenges—from fluctuating inventory levels to dynamic workforce demands. In this new era of logistics and manufacturing, flexibility and safety are no longer optional; they are essential. Enter the Movable Barbed Wire Isolation Grid, a groundbreaking solution designed to meet the complex needs of today’s industrial spaces while enhancing both safety and operational efficiency.

A New Era of Warehouse Management

As industries evolve, so too must the tools and systems that support them. Traditional warehouse layouts are giving way to agile, modular designs that can adapt to seasonal demands, sudden inventory surges, or unexpected workflow disruptions. The Movable Barbed Wire Isolation Grid stands at the forefront of this transformation, offering a versatile alternative to rigid, outdated barriers. Unlike fixed structures, these grids can be easily repositioned to accommodate changing floor plans, ensuring that your space remains optimized at all times.

Why Traditional Barriers Just Don’t Cut It Anymore

For decades, warehouses have relied on permanent fencing and static barriers to manage zones and control access. However, these systems often come with hidden costs—difficult installation, limited adaptability, and high maintenance. In contrast, the Movable Barbed Wire Isolation Grid provides a lightweight yet robust solution that combines strength with mobility. Imagine a system that not only protects sensitive areas but also moves with your operational needs, rather than against them. That’s the promise of modern isolation technology.

What Exactly Is a Movable Barbed Wire Isolation Grid?

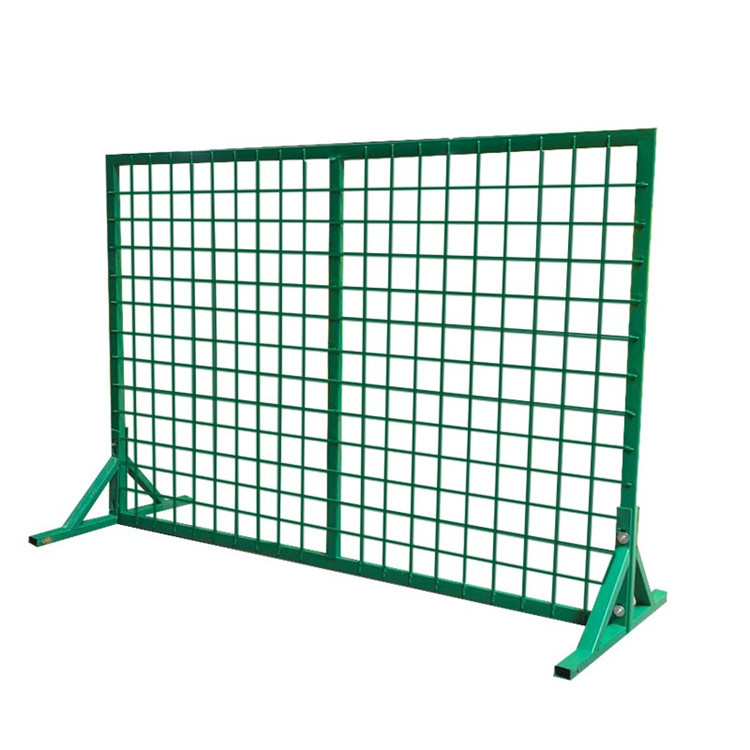

At its core, this system consists of durable, barbed wire mesh panels mounted on mobile frames. Each unit is designed for quick deployment and easy relocation, making it ideal for temporary or semi-permanent installations. The modular nature of the grid allows users to connect multiple units, creating custom layouts tailored to specific warehouse zones such as express sorting areas, restricted zones, or high-risk workspaces. Whether you're managing a distribution center or a manufacturing floor, this isolation grid offers the flexibility you need without compromising on security.

Safety First: How This Fence Net Keeps Your Team Protected

Warehouse environments are inherently dynamic, and with movement comes risk. From forklift traffic to high-value inventory zones, controlling access is crucial to preventing accidents and unauthorized entry. The barbed wire design acts as both a physical and visual deterrent, discouraging trespassing and minimizing the risk of injury. Additionally, the materials used in the grid are built to withstand heavy wear and tear, ensuring long-term reliability even in the most demanding settings. Installation is straightforward, requiring no special tools or expertise—just a few minutes and you're ready to secure your space.

Efficiency Meets Flexibility: The Sorting Revolution

During peak seasons like Black Friday or the holiday rush, logistics centers must scale operations rapidly. The Movable Barbed Wire Isolation Grid excels in these high-pressure environments by enabling quick reconfiguration of sorting zones, staging areas, and loading docks. For example, during a hypothetical “Double 11” event, a logistics facility can deploy multiple grids to create temporary sorting lanes, allowing teams to process packages more efficiently while maintaining clear boundaries. This level of adaptability not only boosts productivity but also enhances safety by minimizing congestion and confusion.

Designed for Diverse Environments: Factories, Warehouses, and More

From automotive assembly lines to electronic component storage, the versatility of this isolation system knows no bounds. Its modular design allows it to be integrated into a wide variety of industrial settings, adapting seamlessly to different spatial constraints. Whether you're securing a hazardous materials zone in a chemical plant or creating a restricted access area in a food processing facility, the Movable Barbed Wire Isolation Grid provides a scalable solution that grows with your business.

Space Optimization: Turning Chaos into Order

One of the most overlooked benefits of the isolation grid is its ability to impose structure on chaotic environments. By clearly defining zones, these grids reduce clutter, streamline movement, and improve overall workflow. Employees benefit from a more organized space that not only enhances safety but also supports better mental clarity and productivity. A clean, well-organized warehouse isn’t just easier to manage—it’s more efficient, more professional, and more pleasant to work in.

Installation & Maintenance: Simpler Than You Think

Unlike traditional fencing solutions that require professional installation and extensive downtime, the Movable Barbed Wire Isolation Grid is designed for simplicity. Each unit rolls smoothly on industrial-grade casters, allowing for easy relocation. Assembly requires minimal tools and no welding or drilling. Routine maintenance is equally hassle-free—just a quick visual inspection and occasional cleaning to ensure optimal performance. With proper care, these grids can serve your facility for years, offering a strong return on investment with minimal upkeep.

Real-World Success Stories

Consider a mid-sized logistics center that struggled with inefficient sorting and unclear zone demarcation during high-volume periods. After implementing the Movable Barbed Wire Isolation Grid, the facility saw a dramatic improvement in both organization and throughput. By using the grids to create dynamic sorting lanes and secure zones, the company was able to cut down on errors and improve turnaround times by over 30%. In another case, a manufacturing plant used the system to establish temporary isolation zones during equipment maintenance, significantly reducing the risk of workplace accidents and improving overall safety compliance.

Future-Proofing Your Warehouse: Adapting to Change

The future of warehousing is undeniably moving toward automation, modular design, and adaptive space management. As AI, robotics, and smart logistics systems become more prevalent, the need for flexible infrastructure will only grow. The Movable Barbed Wire Isolation Grid is more than just a safety tool—it's a strategic asset that prepares your facility for tomorrow’s challenges. By investing in adaptable solutions today, you're not only protecting your team and assets but also positioning your business to thrive in an increasingly competitive and fast-paced industry.

In a world where efficiency and safety are paramount, the Movable Barbed Wire Isolation Grid offers a compelling solution that meets both needs. Whether you're managing a small workshop or a sprawling logistics hub, this innovative system empowers you to take control of your space—safely, efficiently, and affordably. Make the smart move today and discover how this simple yet powerful tool can transform your warehouse environment.