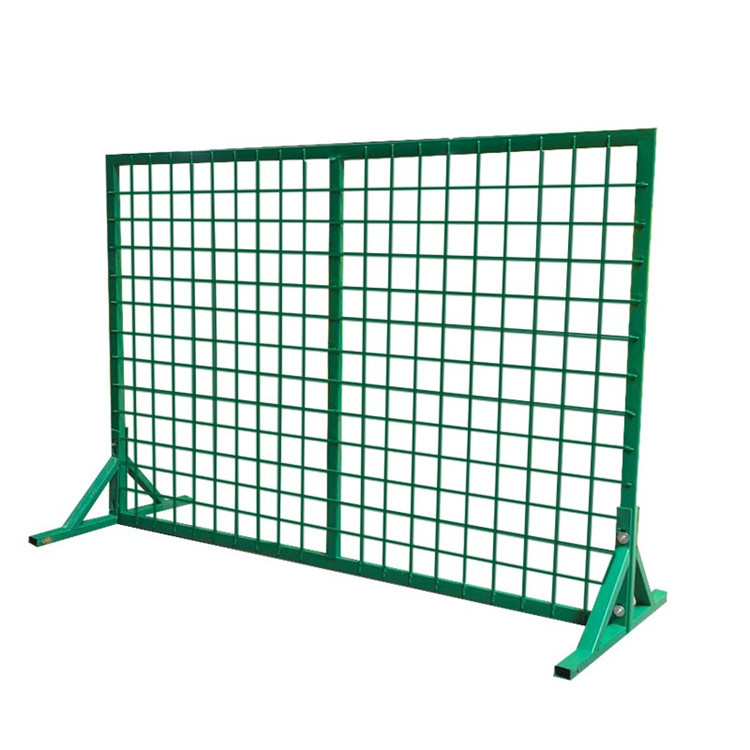

Understanding Movable Barbed Wire Isolation Grids

Movable barbed wire isolation grids are innovative solutions designed to enhance the security and efficiency of warehouse management. These grids are constructed from durable barbed wire, offering a flexible and adaptable means to isolate different zones within a warehouse. Their primary purpose is to prevent unauthorized access, protect valuable inventory, and improve overall organization within the warehouse space.

The concept of using barbed wire for security has evolved significantly over the years. Initially used in agricultural settings, barbed wire has found its way into various industrial applications, including warehouse management. The evolution of these isolation grids reflects a growing need for robust and adaptable security measures in modern warehouses.

Key Benefits for Warehouse Efficiency

Enhanced Security Measures

Movable barbed wire isolation grids significantly enhance warehouse security. By preventing unauthorized access, they offer a reliable barrier that protects valuable inventory from theft and damage. This added layer of security is crucial for maintaining the integrity of warehouse operations.

Improved Organization

These grids allow for the effective segregation of different warehouse zones. By delineating specific areas for various types of inventory or operations, they streamline workflow and movement within the warehouse. This improved organization leads to increased efficiency and productivity.

Flexibility and Adaptability

One of the standout features of movable barbed wire isolation grids is their flexibility. They can be easily reconfigured based on changing needs, making them ideal for warehouses that experience frequent layout adjustments. Additionally, they offer scalability for growing operations, ensuring that the security measures can expand alongside the business.

Installation Process

Pre-installation Assessment

The installation process begins with a thorough pre-installation assessment. This involves evaluating the warehouse layout and identifying high-risk and high-traffic areas. Understanding these factors is crucial for planning an effective grid layout.

Choosing the Right Materials and Tools

Different types of barbed wire are suitable for various warehouse environments. Selecting the appropriate materials and tools is essential for ensuring a secure and durable installation. Necessary equipment includes tensioning devices and secure foundations to anchor the grids.

Step-by-Step Installation Guide

Installing movable barbed wire isolation grids involves several key steps. Begin by planning the grid layout, ensuring that all high-risk areas are adequately covered. Next, secure the grid foundations to provide stability. Finally, install and tension the barbed wire to create a secure barrier.

Maintenance and Upkeep

Regular Inspection Protocols

Maintaining the integrity of movable barbed wire isolation grids requires regular inspections. Identifying wear and tear early ensures that minor damages can be addressed before they compromise security. Regular checks are essential for ensuring the structural integrity of the grids.

Repair and Replacement Guidelines

Addressing minor damages promptly can prevent more significant issues. Procedures for replacing sections of the grid should be in place to ensure that the system remains secure and effective. Timely repairs and replacements are crucial for maintaining optimal security levels.

Safety Tips for Maintenance Personnel

Safety is paramount when handling barbed wire. Maintenance personnel should wear proper protective gear and follow safe handling practices. These measures help prevent injuries and ensure that the maintenance process is carried out efficiently.

Case Studies and Real-World Applications

Movable barbed wire isolation grids have proven successful in various industries. Logistics and distribution centers, for example, have utilized these grids to enhance security and streamline operations. Manufacturing plants have also benefited from the improved organization and flexibility offered by these grids.

Lessons learned from these applications highlight common challenges and solutions. Industry experts recommend specific strategies for optimizing warehouse layouts and balancing security with accessibility. These best practices can help other warehouses implement effective isolation grid systems.

Cost-Benefit Analysis

Investing in movable barbed wire isolation grids involves initial costs for materials and installation. However, the long-term savings from reduced theft and damage can offset these expenses. A thorough cost-benefit analysis reveals that the return on investment is significant, thanks to improved productivity and enhanced safety.

Considering the reduction in liability and the added security, these grids offer a compelling ROI for warehouse operations. Businesses can expect to see a marked improvement in overall efficiency and a decrease in losses due to theft or damage.

Future Trends in Warehouse Security and Management

Innovations in isolation grid technology are on the horizon. Smart grids with integrated sensors are becoming increasingly popular, offering real-time monitoring and control. These advancements enhance the security and functionality of isolation grids, making them even more effective.

Integration with other security systems, such as surveillance cameras and access control systems, is another emerging trend. This holistic approach to warehouse security ensures comprehensive protection and streamlined management.

FAQs and Expert Advice

Common questions about movable barbed wire isolation grids often revolve around safety and usability. Addressing these concerns is key to ensuring that businesses feel confident in implementing these systems. Expert tips can help optimize warehouse layout, ensuring efficient grid placement and a balance between security and accessibility.

Final Thoughts and Next Steps

Proactive warehouse management is essential for maintaining security and efficiency. Movable barbed wire isolation grids offer a practical solution for achieving these goals. For further reading and professional consultation, businesses can contact suppliers and installation experts to explore the best options for their specific needs.

For more information on our range of products, including warehouse isolation grids, visit Hohuang Wire Mesh Co., LTD.