Understanding Warehouse Isolation Grids

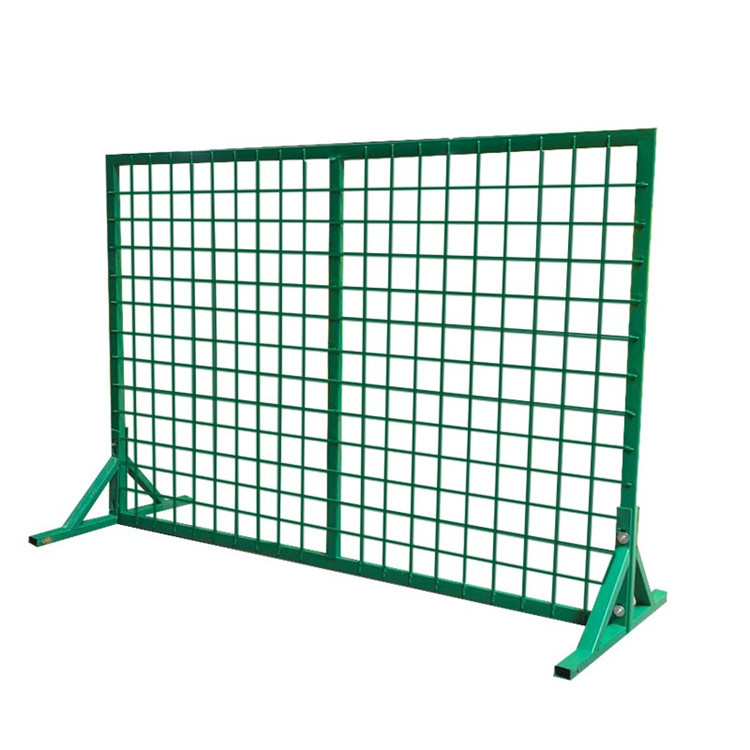

Warehouse isolation grids are physical barriers used to segregate different areas within a warehouse. These grids have evolved significantly from simple partitions to complex systems designed to enhance operational efficiency, security, and safety. Modern facilities use various types of isolation grids, such as movable barbed wire and express sorting fences, to meet their specific needs.

Enhancing Operational Efficiency

One of the primary benefits of warehouse isolation grids is the segregation of different operational zones. These grids create distinct areas for goods receiving and inspection, storage and retrieval, and packaging and dispatch. This segregation helps streamline workflow through organized pathways, reducing the risk of cross-contamination and mix-ups.

By clearly defining operational zones, warehouses can ensure that each area operates independently yet cohesively within the larger workflow. This organized approach minimizes errors and enhances overall productivity.

Boosting Security Measures

Warehouse isolation grids play a crucial role in controlling access to sensitive areas, preventing unauthorized entry and theft. By isolating specific zones, warehouses can implement surveillance systems more effectively, ensuring that high-value goods are protected. Case studies have shown that the use of isolation grids can significantly enhance security measures, reducing the risk of theft and loss.

Improving Safety Protocols

Clear boundaries defined by warehouse isolation grids help minimize accidents by ensuring that different areas are used for their intended purposes. For example, the safe storage of hazardous materials is more manageable when these materials are isolated from other goods. Compliance with health and safety regulations is also more straightforward when there are well-defined zones.

Real-life examples demonstrate that the implementation of isolation grids can lead to significant improvements in workplace safety, reducing the number of accidents and ensuring a safer environment for employees.

Facilitating Inventory Management

Warehouse isolation grids simplify tracking and auditing processes by providing clear demarcations between different storage areas. This organization makes stock rotation and replenishment more efficient and less prone to errors. When integrated with warehouse management systems (WMS), isolation grids can significantly improve inventory accuracy, leading to better resource utilization and reduced wastage.

Cost-Effectiveness of Isolation Grids

While the initial setup costs of warehouse isolation grids may be significant, the long-term savings they offer are substantial. These grids reduce loss and damage of goods, leading to lower replacement costs. Additionally, the efficiency gains from organized workflows and improved inventory management can result in lower labor costs. Industry experts have conducted ROI analyses, demonstrating that the investment in isolation grids pays off over time.

Customization and Scalability

Warehouse isolation grids can be tailored to meet specific needs, with modular designs allowing for future expansion. This adaptability makes them suitable for various industries and types of goods. Businesses that have scaled with isolation grids often provide testimonials highlighting the grids' flexibility and effectiveness in meeting their evolving requirements.

Implementation Best Practices

For seamless installation of warehouse isolation grids, it is essential to assess your facility’s unique requirements, choose the right materials and grid design, and follow best practices. Common pitfalls, such as improper material selection or inadequate planning, can be avoided with careful consideration and expert guidance.

Future Trends in Warehouse Isolation

Technological advancements are shaping the future of warehouse isolation grids. Integration with IoT and smart warehouse technologies enables predictive maintenance and automated adjustments, enhancing efficiency and reducing downtime. Experts predict that these innovations will continue to evolve, offering even more sophisticated solutions for warehouse management in the next decade.