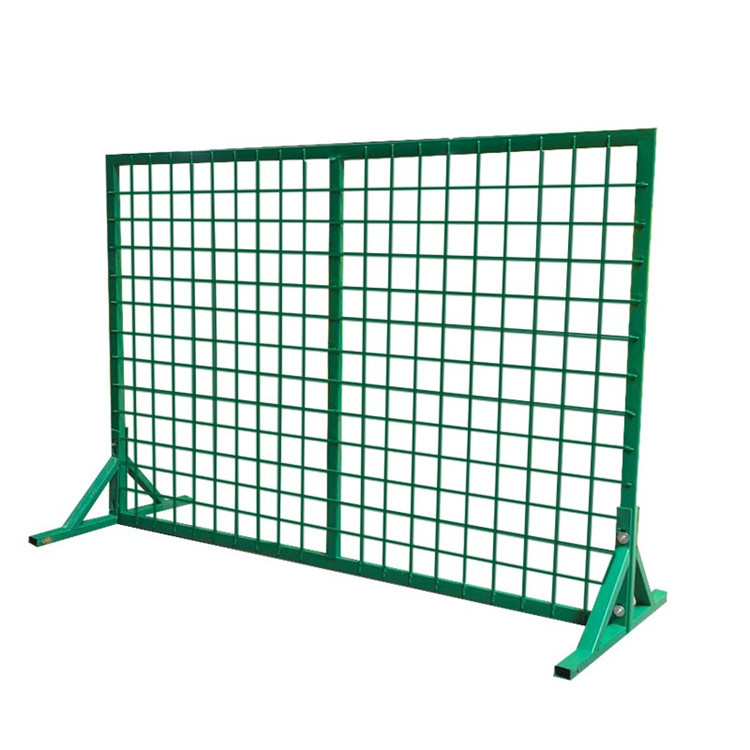

A high-strength movable barbed wire fence securing a dynamic warehouse sorting zone.

When Space Needs to Speak: Redefining Warehouse Logic with Mobility

In today’s fast-paced logistics landscape, warehouses and sorting centers are no longer static environments. The demand for rapid reconfiguration—driven by seasonal peaks, shifting workflows, or evolving automation—has exposed the limitations of traditional fixed fencing. Concrete barriers and permanent metal grids may offer durability, but they lack adaptability. What happens when yesterday’s packaging zone becomes tomorrow’s equipment storage? This is where the concept of “movable” transforms from convenience to necessity. Enter the mobile barbed wire fence: not just a barrier, but a strategic tool for spatial intelligence. It empowers warehouse managers to redefine zones on the fly, ensuring safety without sacrificing agility.

Deployed in an express sorting facility, this fence provides immediate visual and physical separation.

The Evolution of Barbed Wire: From Borderlines to Industrial Guardians

Once synonymous with military zones and restricted borders, barbed wire has undergone a quiet revolution in industrial design. Modern perceptions have shifted—today, it’s recognized not as a symbol of exclusion, but as a calculated layer of controlled deterrence. In high-traffic sorting hubs, where unauthorized access can lead to accidents or operational delays, the psychological and physical presence of barbed wire acts as a powerful preventive measure. But appearance isn’t everything; performance matters more. Our movable fences use high-tensile steel wires, precision-welded into rigid panels and coated with anti-corrosion zinc and powder finishes. The result? A structure that resists tampering, withstands impacts, and maintains integrity even under harsh warehouse conditions—sun, dust, moisture, and constant movement.

The Secret Behind Modular Design: Building Safety Like a Puzzle

Flexibility begins with modularity. Each section of the movable barbed wire fence connects via a secure yet tool-free coupling system, allowing teams to assemble, disassemble, or reconfigure boundaries in minutes. Imagine transforming a wide-open floor into segmented work cells during morning shifts, then consolidating space for overnight machinery storage—all without construction crews or downtime. Integrated swivel casters enable smooth relocation across concrete surfaces, while locking brakes ensure absolute stability once positioned. Whether isolating a hazardous conveyor junction or cordoning off inventory awaiting dispatch, these fences adapt as seamlessly as your operations evolve.

Modular sections connect easily, enabling quick deployment and layout changes.

Safety Beyond Blocking: Enhancing Personnel Flow and Goods Movement

True security doesn’t just stop intrusions—it guides behavior. The sharp visibility of the barbed wire mesh serves as a constant visual cue, discouraging foot traffic into restricted or high-risk zones. In express sorting environments, where workers move swiftly among automated belts and forklift paths, clearly defined perimeters reduce the risk of accidental entry. One logistics client reported a 60% drop in near-miss incidents after installing these fences around robotic palletizing stations. When combined with signage and CCTV coverage, the fence becomes part of a layered safety ecosystem—one that protects people, prevents damage, and keeps operations flowing smoothly.

The Value Equation: Factory-Direct Quality That Cuts Costs

Bypassing intermediaries means more than lower prices—it means better value. By sourcing directly from manufacturing facilities, customers gain access to premium materials and rigorous quality control at competitive rates. Whether outfitting a small urban delivery hub or a sprawling regional distribution center, scalable production allows for tailored quantities and configurations. And because these fences are built to last over a decade with minimal maintenance, the long-term savings are substantial. Compared to temporary plastic barriers that degrade quickly or custom-built walls requiring demolition later, this solution offers lasting durability without long-term commitment.

Tool-free installation empowers staff to set up or modify fences independently.

Installation Is Just the Beginning: Where Efficiency Takes Root

Setting up the fence requires no specialized tools or technical training—just two people and a few minutes. Panels snap together, wheels roll into place, and locks engage securely. Routine inspections are simplified thanks to visible weld points and replaceable components; damaged sections can be swapped out without replacing entire units. Users consistently report a shift in perception—from viewing the fence as a “temporary fix” to adopting it as a standard operational feature. One warehouse manager noted, “It’s now part of our daily setup checklist. We move it like we move pallets.”

The Warehouse of Tomorrow: Where Passive Meets Intelligent Protection

Looking ahead, passive barriers like these are poised to become active participants in smart warehouse ecosystems. Picture a movable fence embedded with vibration sensors that trigger alerts upon impact, or integrated RFID tags that log relocation events for audit trails. Future iterations could sync with AI-powered surveillance systems, automatically adjusting virtual geofences in real time as physical barriers shift. As automation expands, so too must the adaptability of safety infrastructure. These fences aren’t just keeping pace—they’re laying the groundwork for responsive, intelligent industrial spaces.

A fully optimized warehouse using multiple movable fences for dynamic area management.

The future of warehouse safety isn’t rigid—it’s responsive. With the movable barbed wire fence, protection becomes as agile as your supply chain. Discover how this innovation is setting new standards in industrial security, one reconfigurable boundary at a time.