Movable Barbed Wire Isolation Fence for Warehouses & Workshops – Secure, Durable & Easy to Install

When it comes to securing industrial spaces, safety has long been synonymous with permanence. Fixed fences, bolted into concrete, have dominated warehouses and workshops for decades. But what happens when your operational needs shift faster than your infrastructure can adapt? In today’s dynamic logistics and manufacturing environments, rigid barriers are no longer enough — they’re often in the way.

When Security Meets Flexibility: Redefining Boundaries in Industrial Spaces

Traditional fencing systems were designed for stability, not agility. Yet modern warehouses face constant change — from seasonal reconfigurations to sudden layout shifts during peak sorting periods. Permanent structures hinder workflow, increase downtime during renovations, and fail to accommodate temporary high-risk zones. The rise of express logistics, just-in-time manufacturing, and agile production lines demands a smarter approach.

This is where the concept of mobility transforms from convenience to necessity. A fence that can be repositioned in minutes isn’t just practical — it’s a strategic asset. Imagine isolating hazardous machinery during maintenance without weeks of construction, or cordoning off overflow inventory during holiday rushes with zero permanent modification. That’s the power of a truly adaptable safety solution.

Steel Mesh, Mobile Shield: Why This Isolation Fence Stands Apart

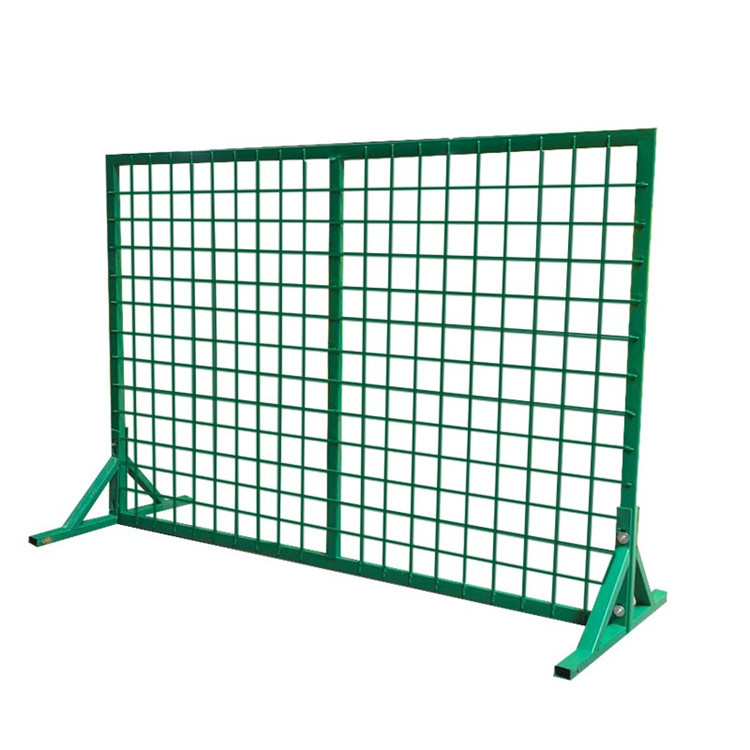

Built from high-tensile galvanized steel wire and coated with anti-corrosion materials, this movable isolation fence delivers military-grade durability in an industrial package. The robust weave resists impact, tampering, and environmental wear, ensuring years of reliable service even in harsh workshop conditions.

The integrated barbed wire design isn’t just symbolic — it acts as a powerful psychological and physical deterrent against unauthorized access. Combined with a tight mesh pattern, it prevents climbing and discourages intrusion far more effectively than plain chain-link alternatives.

What truly sets this system apart is its modular architecture. Panels connect seamlessly like building blocks, allowing you to extend, shorten, or reshape enclosures based on real-time spatial needs. Whether you're creating a 10-meter buffer zone or enclosing an entire sorting bay, the setup adapts effortlessly.

Real-World Performance: How It Holds Up in High-Pressure Sorting Hubs

Picture this: a bustling logistics center at peak hour. Forklifts dart between stacks of packages, workers rush to meet dispatch deadlines, and pedestrian pathways intersect with vehicle routes. Without clear demarcation, chaos ensues — and so do accidents.

One major e-commerce fulfillment center faced exactly this challenge. After deploying these movable barbed wire fences to separate automated sorting lines from manual packing stations, they saw a 40% drop in near-miss incidents within three months. Supervisors reported improved compliance with traffic protocols, and floor managers praised the clarity the visual boundary provided.

The ability to quickly reconfigure zones during equipment upgrades meant zero operational downtime — a game-changer compared to previous concrete-based partitions that took days to modify.

Installation Made Effortless: Set Up a Secure Zone in Minutes

Gone are the days of hiring contractors and scheduling multi-day installations. This fence arrives pre-assembled, with intuitive connectors that snap into place. The entire deployment process breaks down into three simple steps: unfold the panel, link it to the next section, and secure it with ground anchors or optional base weights.

A single technician can install a 6-meter stretch in under ten minutes — no tools required. And thanks to optional wheeled base attachments, entire sections can be rolled aside during cleaning or relocated during facility reorganization. Need to shift a perimeter after a machine relocation? Done before lunch.

More Than a Fence: An Invisible Tool for Smarter Space Management

Beyond physical security, this system functions as a silent guide for workforce behavior. Clearly defined boundaries help employees instinctively recognize restricted areas, reducing accidental entries into danger zones. Color-coded variants (available upon request) further enhance visibility for specific hazard types.

Its applications stretch beyond warehouses — think repair bays needing temporary containment, outdoor storage yards during audits, or construction perimeters within live production floors. Each use case benefits from the same core advantage: responsive security that grows and shifts with your operations.

Voices from the Field: What Users Love About the Unexpected Details

"We were worried the fence would obstruct forklift movement," shared a logistics supervisor from a Midwest distribution hub. "But the vertical clearance and corner radius allowed full maneuverability — no adjustments needed."

Security leads consistently praise the retro-reflective strips embedded along the top rail, which dramatically improve nighttime visibility. One facility manager noted, “During night shifts, the glow makes the barrier impossible to miss — it’s like a safety halo.”

Maintenance teams appreciate the low upkeep. “Three years in, no part replacements,” said a plant engineer. “A quick wipe-down keeps it looking sharp. No rust, no sagging.”

Future-Ready Protection: Building Infrastructure That Can Grow

In the age of Industry 4.0, static assets are liabilities. Smart factories demand flexible, scalable solutions across all layers — including physical security. The old model of “build once, forget forever” no longer aligns with lean, adaptive operations.

Investing in a movable isolation system isn’t just about buying a fence — it’s about future-proofing your facility’s layout strategy. It reflects a mindset shift: security should empower agility, not restrict it.

If Your Facility Faces These Challenges, This Could Be Your Solution

Are you redesigning your parcel flow? Managing fluctuating space demands during peak seasons? Tired of costly demolition every time you rearrange the floor plan? Or striving to tighten control without adding more supervisors?

Each of these pain points signals an opportunity — to replace rigidity with resilience, and turn your safety infrastructure into a dynamic tool. This isn’t just another warehouse fence. It’s a mobile shield, ready to move when you do.

Step into the next generation of industrial safety. Where strength meets flexibility, and protection finally learns to walk.