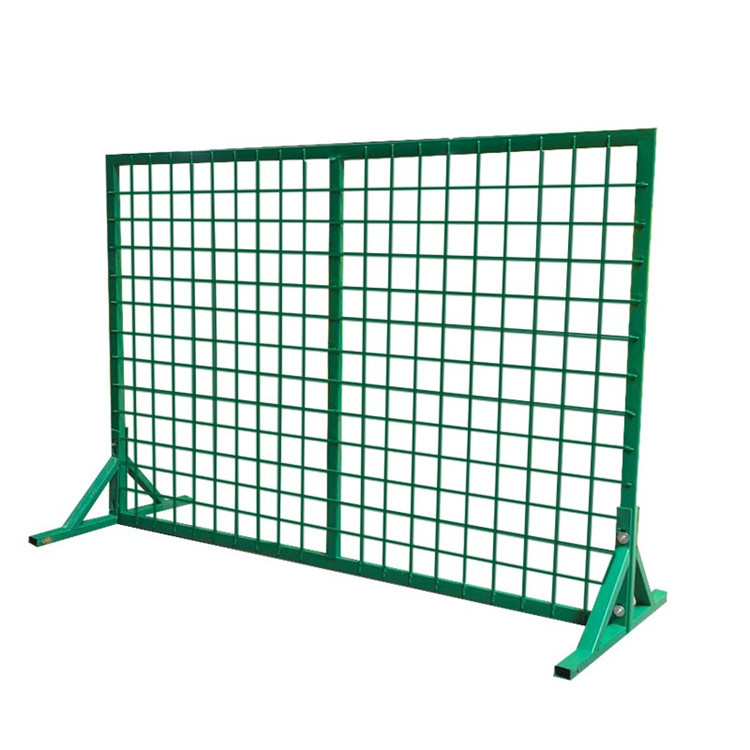

Movable Barbed Wire Fence for Warehouse Isolation – Secure & Flexible Workshop Safety Net

When Space Starts Speaking: The Invisible Rules and Visible Boundaries of Warehousing

The morning light spills across the concrete floor as conveyor belts hum to life. Packed parcels race down chutes, forklifts weave through narrow lanes, and workers coordinate like a well-rehearsed ensemble. In this rhythm of urgency, one thing becomes clear: chaos is inevitable—unless boundaries are drawn not just in policy, but in steel.

How do you create a boundary that moves as quickly as your workflow? How can a physical barrier be both unyielding and adaptable? The answer lies not in walls, but in intelligent isolation systems designed for modern logistics. Enter the era of the movable barbed wire fence—a solution where security meets scalability, and safety evolves with demand.

The Evolution of Barbed Wire: From Borderlines to Smart Industrial Guardians

Once reserved for military perimeters and prison yards, barbed wire has undergone a quiet revolution. No longer a symbol of restriction alone, it now serves as a strategic tool in high-efficiency environments—from distribution hubs to manufacturing floors.

The key shift? Mobility. Unlike traditional fixed fencing, today’s industrial-grade barriers are built to move. Imagine a major logistics center facing an unexpected surge in volume. Instead of halting operations for days to rebuild static partitions, they deploy movable barbed wire fences. Within three hours, new zones are established, traffic flows redirected, and productivity preserved—all without welding torches or bureaucratic delays.

This isn’t temporary patchwork. It's engineered agility.

More Than Just a Fence: The Five Design Principles Behind High-Strength Movable Barbed Wire Systems

Beneath its rugged appearance lies a carefully engineered system built for real-world demands.

The Power of the Frame: Constructed from cold-rolled steel with anti-corrosion coating, each unit withstands heavy impacts while resisting rust—even in humid or chemically active environments. This isn't flimsy mesh on poles; it's structural resilience on wheels.

Controlled Deterrence: The high-tension barbed strands aren't meant to harm—they’re designed to discourage unauthorized access. Strategically spaced and tightly tensioned, they offer visual and psychological warning without compromising workplace safety.

The Secret in the Wheels: Heavy-duty silent casters allow a single worker to reposition a full panel effortlessly. These aren't afterthoughts—they're precision components enabling smooth navigation over uneven surfaces while locking securely into place when needed.

Modular Intelligence: Thanks to a smart interlocking mechanism, multiple units connect seamlessly into L-shapes, U-formations, or complete enclosures. Need to isolate a repair zone? Snap together four panels in minutes. Done? Break them apart and store flat.

Respect for the Floor: Equipped with non-slip base plates and protective foot guards, these fences protect polished epoxy flooring from scratches and scuffs—because efficiency shouldn’t come at the cost of facility integrity.

Creating Order in Chaos: Real-World Applications That Redefine Flexibility

In practice, the value of this system shines brightest under pressure.

At a national parcel hub during peak season, managers use movable barbed wire fences to adjust buffer zones between automated sorters and manual loading docks. As inbound volumes fluctuate by shift, so too does the perimeter—shrinking or expanding within 15-minute windows to optimize space usage.

In automotive workshops, technicians deploy the nets around machinery undergoing maintenance. Gone are the days of fragile caution tape fluttering in drafts—now, a robust, instantly recognizable barrier keeps personnel out until work is complete.

And for storage areas holding high-value electronics, nighttime brings automatic enclosure. By dusk, sections merge into a secure compound; by dawn, they’ve been dismantled to reopen loading corridors—no crane, no crew, no compromise.

Safety Reimagined: Unexpected Benefits Beyond Physical Protection

The impact goes deeper than accident prevention. Employees report greater confidence knowing clearly defined zones exist—not arbitrary lines taped to the ground. This subtle shift fosters better compliance, reducing near-misses caused by misjudged proximity.

Managers find themselves planning ahead, using the fences as visual tools in layout simulations. When paired with signage and LED indicators, the system transforms into a behavioral guidance network—shaping movement patterns before incidents occur.

If Fences Could Think: What’s Next for Industrial Isolation?

The future points toward integration. Picture sensors embedded in fence posts detecting vibrations or attempted breaches, sending alerts directly to supervisors’ tablets. Envision AI-driven warehouse management systems (WMS) triggering automatic deployment based on scheduled tasks—fences rolling into position autonomously before hazardous operations begin.

Sustainability also plays a role. With increasing use of recycled steel and modular designs minimizing waste, tomorrow’s barriers will protect more than people—they’ll safeguard resources too.

Dispelling Myths: Flexibility Does Not Mean Fragility

A common misconception persists: if it moves, it must be weak. But stress tests tell another story. In simulated collisions, movable barbed wire units absorbed impact comparably to welded permanent structures—thanks to reinforced joints and low-center stability design.

This is *engineering-grade flexibility*: change without compromise. One warehouse supervisor put it best: “We brought it in as a temporary fix during renovation. Two years later, it’s still our most trusted line of defense.”

Three Questions Every Site Manager Should Ask Today

Could your current isolation system be reconfigured in under 30 minutes? Or does it require permits, tools, and downtime? When your next production line goes live, will you need to cut metal—or simply roll out a few panels?

And perhaps most telling: do your team members routinely step over warning tape because they don’t believe it matters?

If any of these questions give you pause, it may be time to rethink what safety looks like. Because true protection isn’t rigid—it’s responsive. And in the fast-moving world of warehousing and manufacturing, responsiveness is everything.